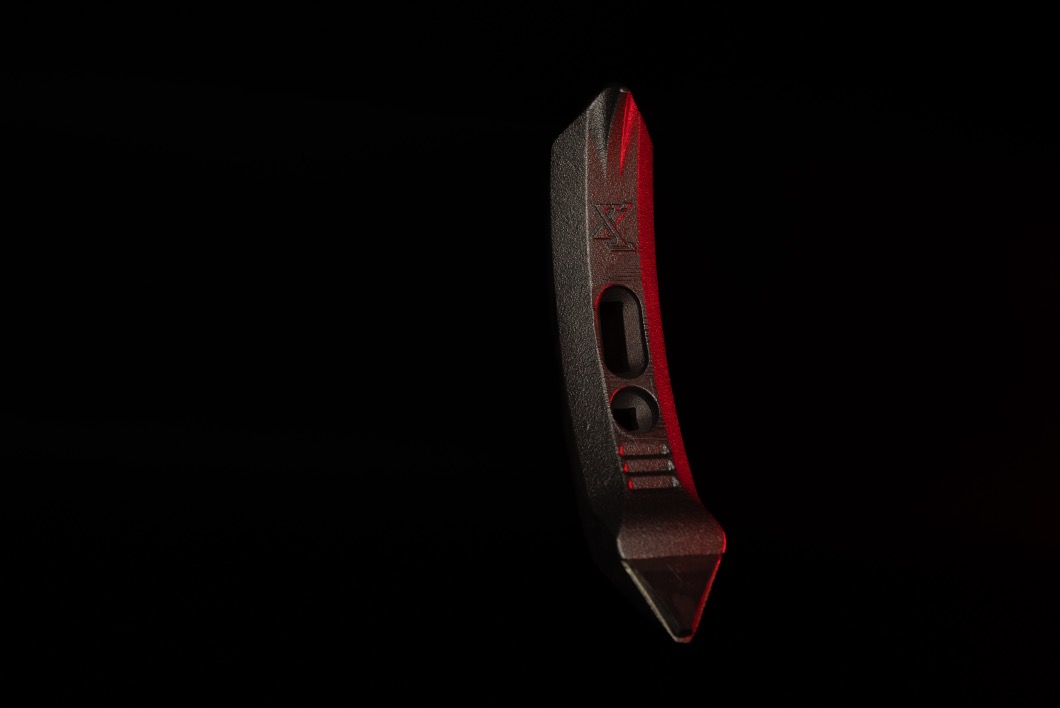

The Industriehof "eXtreme" Carbide Line is specifically designed to meet the needs of farmers. Especially during the peak season, it is important for farmers to work with reliable machines and wearing parts: Wearing parts that can withstand high loads, enable a good soil mixture ratio, providing good value for money. We have accepted these requirements as a valid challenge, and are responding with our range of "eXtreme" wearing parts, based on many years of agricultural experience.